On the canonical Ford T, the first mass-produced car of mankind, there were Bosch candles, which looked just like modern ones. The same steel case with a hexagon, a ceramic insulator cone, a pair of electrodes, the same dimensions, proportions … Well, what a genius you need to be to design a part once and for all – more than 100 years ahead!

Perhaps the secret of engineering foresight is that in 1902, the Bosch Precision Mechanics Workshop designed not only a spark plug, but a complete ignition system that included a high-voltage magneto and wiring. Since then, engineers have not tired of repeating that candles cannot be considered separately from a particular engine.

For ordinary users, this means that any ignition problems must be dealt with comprehensively and directly on the car. And even if suspicions fall on the candles, they need to be diagnosed on the engine. Since it’s not just that each engine, each cylinder “sets” the candle its own working conditions: somewhere the mixture is a little poorer, somewhere the compression is worse or vice versa, the pressure is higher, somewhere the wires are “tired”, and the coil with an interturn circuit produces less voltage … And also – condensate under the hood and old soot on the wires, a cracked tip, an old battery – there are many reasons for ignition failures, and you can’t blame everything on candles!

Therefore, even tests of candles in a special pressure chamber cannot be considered absolutely correct – or rather, such boxes cannot be used for diagnostics at all. Boxing is not able to recreate conditions similar to those that affect a spark plug in a particular engine. That is why for different engines they create different candles. The use of such equipment indicates the low competence of the masters of this service.

So the engine needs to be diagnosed where there is modern diagnostics – devices that evaluate the state of several systems of the power unit at once. The options “replace candles” or “flush the injector” should be discarded immediately.

Yes, there were times when experienced craftsmen, without touching the candles, without unscrewing a single nut on the machine, with only an oscilloscope, could determine the gap of the candle, the condition of the coil and the adjustment of the distributor. They could even detect air leaks into the cylinders through a damaged gasket – and this is from a single waveform on a flickering screen the size of a pack of cigarettes! The time for such diagnostics has passed: today there are wonderful devices such as Bosch KTS and the ESI [tronic] program.

And finally, just killer numbers from the diagnosticians of the worldwide Bosch Auto Service network. Do you know what is the reason for 90% of complaints about the work of candles? In their wrong installation! Although, it would seem, what is simpler – he twisted the thread from the heart and planted the tip tighter: backwater! The main mistake: tighten the candles in the head with excessive force. The diameter and length of their threaded part is impressive, M10 – M18 and 10 – 27 mm, respectively, physically it can withstand a tightening torque of 60 – 110 Nm.

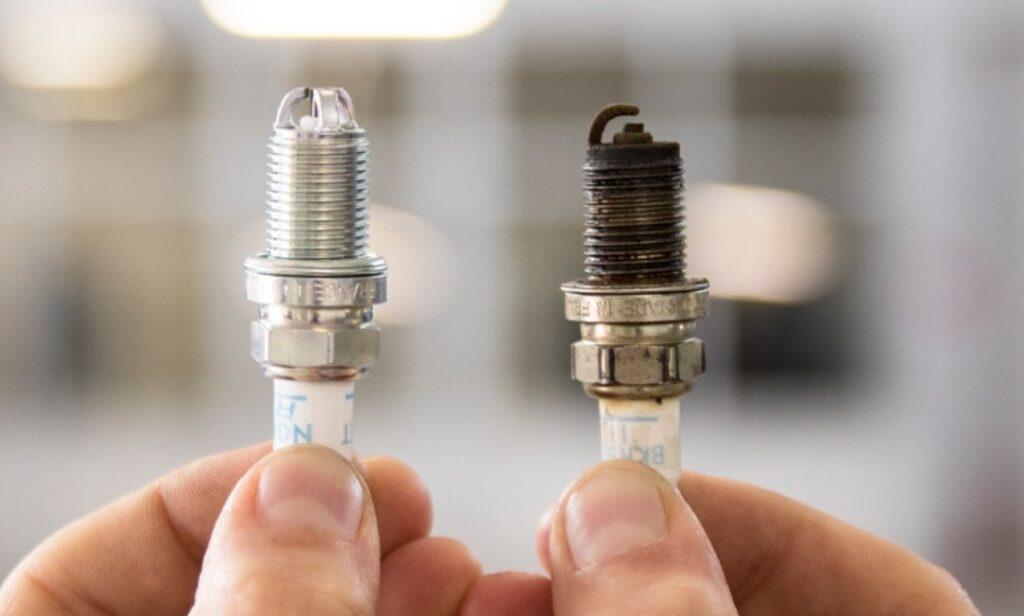

Meanwhile, the tightening torque of the candle is about 15 – 25 Nm, depending on the material of the block head. And with excessive tightening, the heat exchange of the candle and the head is disturbed (that’s why the threaded part is made so massive!), The candle overheats and loses its specified characteristics. And most importantly: if the candle tightening regulations are violated, cracks form in the ceramics, and the insulator separates from the body. As a result of these metamorphoses – unstable start-up, misfiring, excessive fuel consumption … A damaged spark plug can travel several thousand kilometers, and then simply “crumble” into the combustion chamber, damaging the engine. And if this happens at high speed, and even when overtaking?

If you want to test your mechanic’s competence, ask him how to properly tighten the spark plug if there is no torque wrench? Hint – for a thread, for example, M12x1.25, the tightening torque is 23 Nm. If there is no torque wrench, then you need to screw the candle by hand until it stops, and then turn it 90 degrees with a standard key.